- About Us

- Return Policy

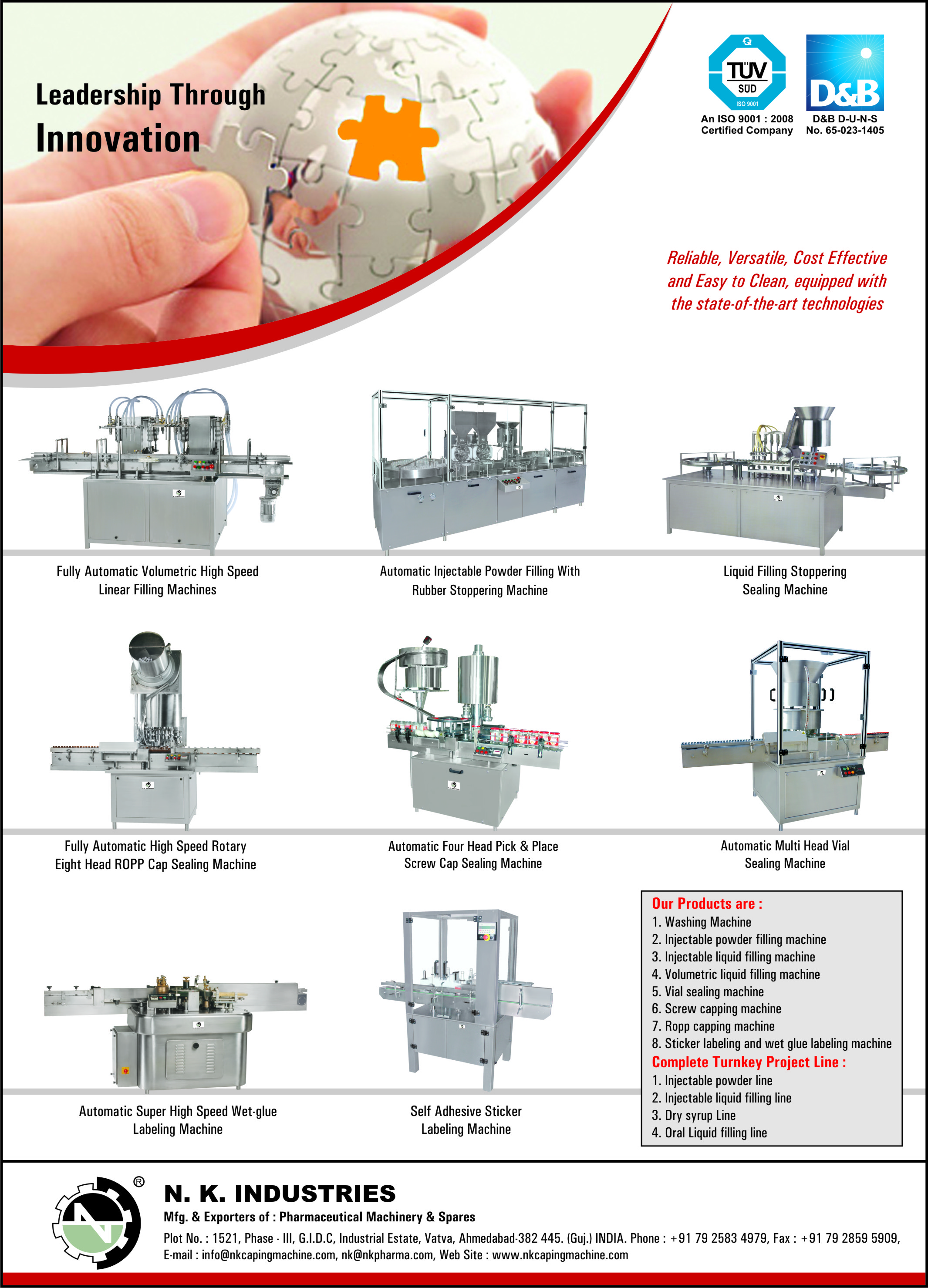

- Complete Turnkey Line

- Products

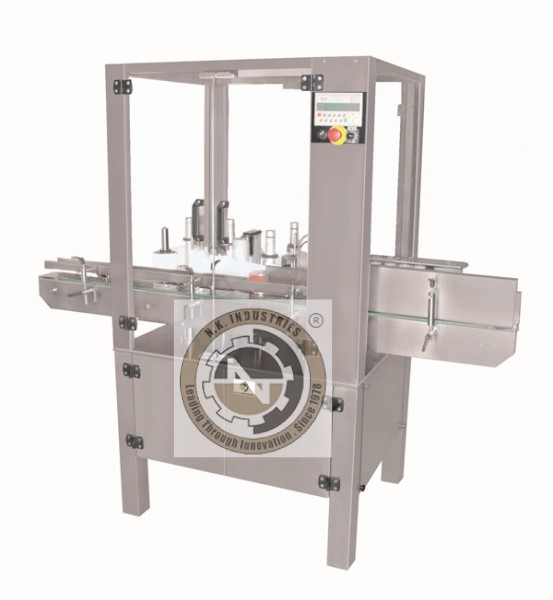

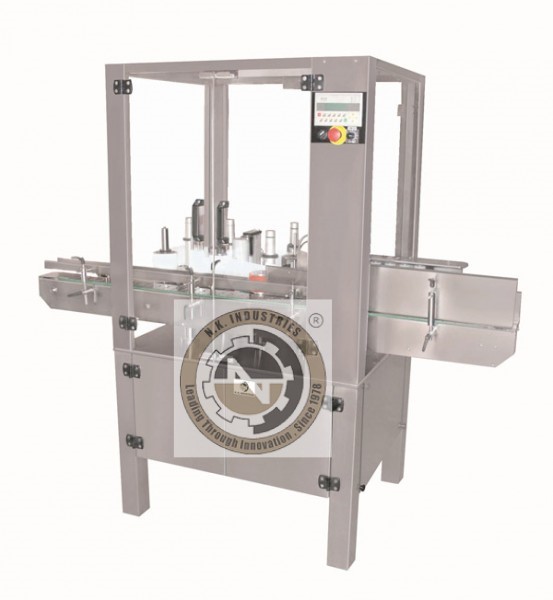

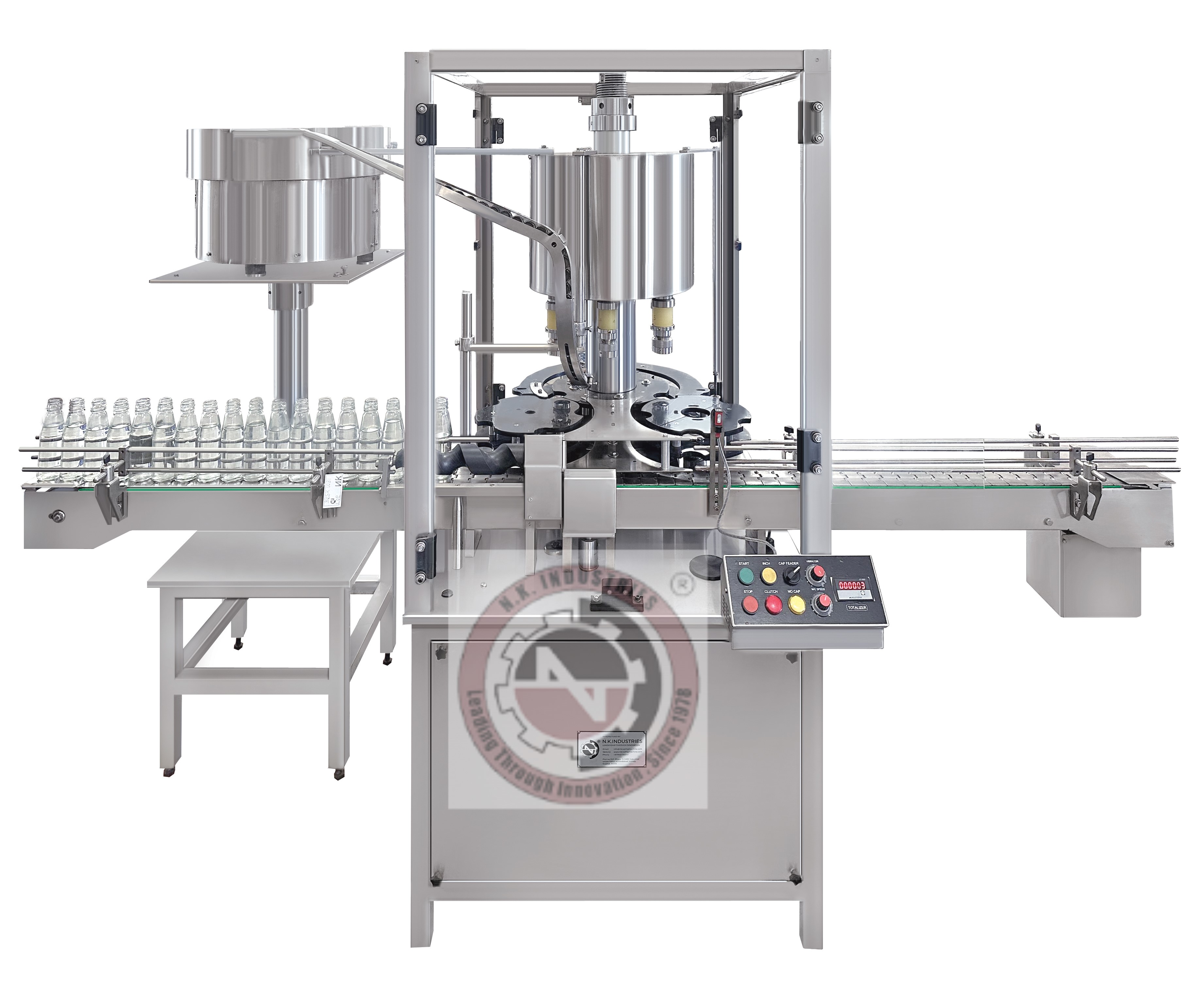

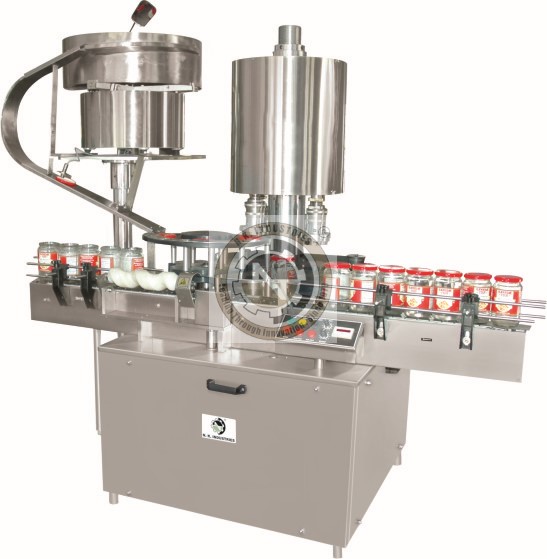

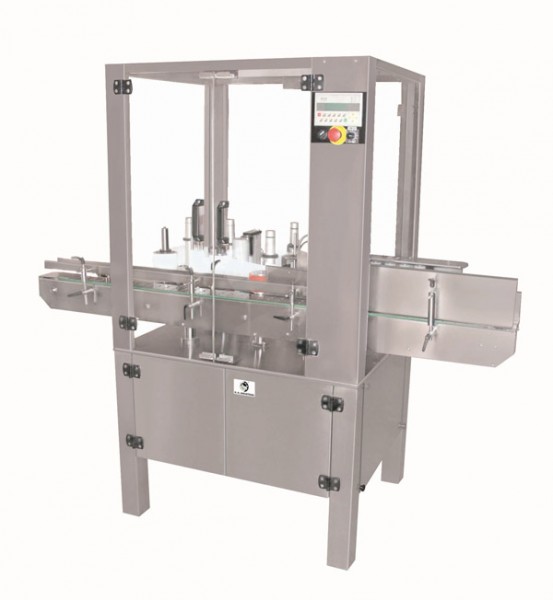

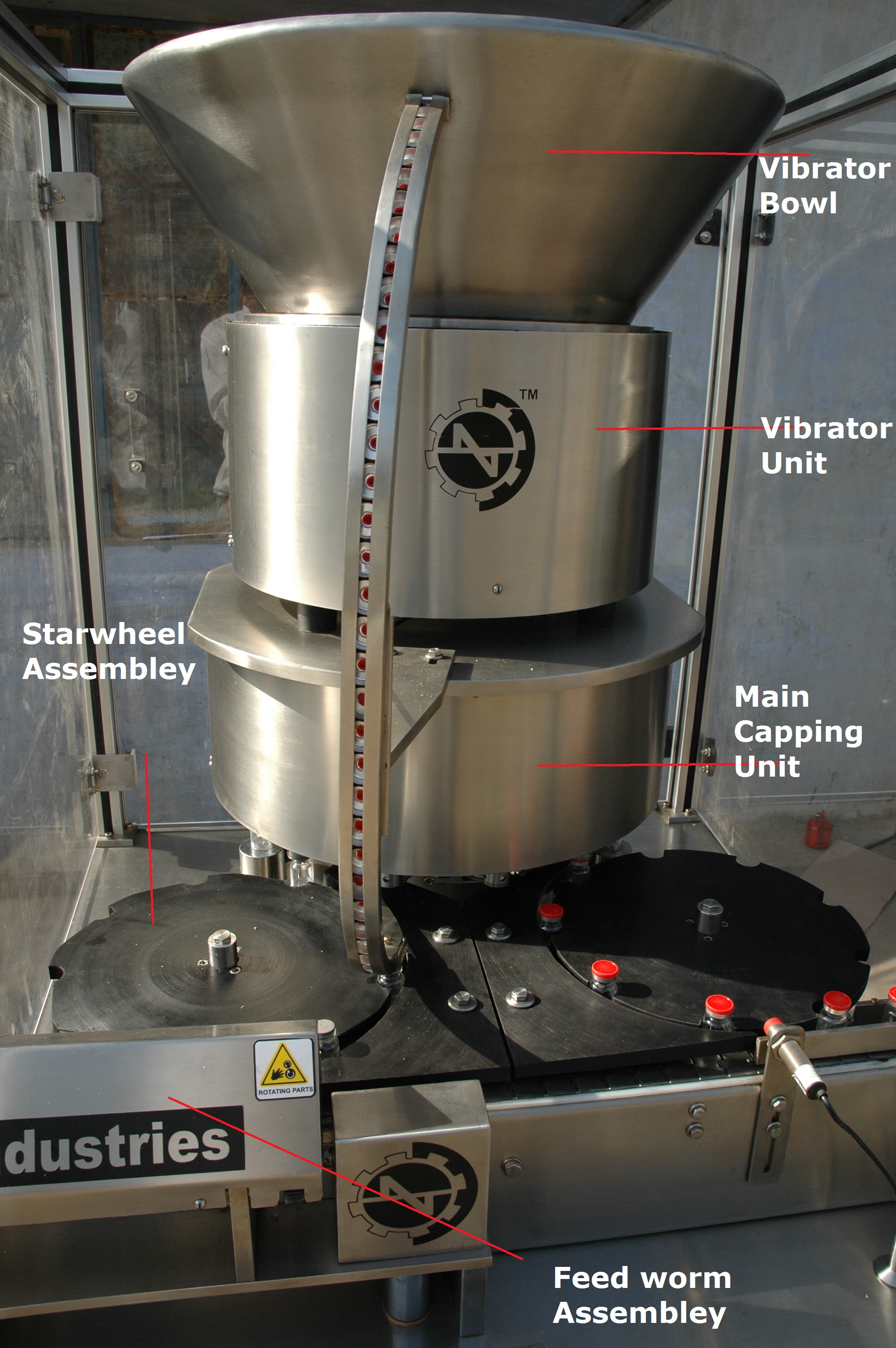

- Capping Machine

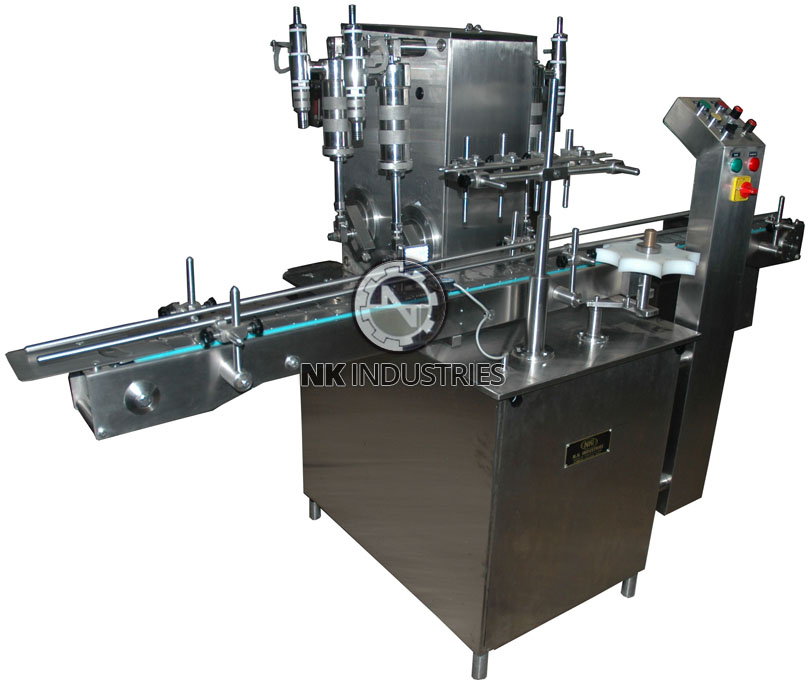

- Labeling Machine

- Sticker Labeling Machine

- Automatic Round Bottle Sticker Labeling Machine

- Automatic Vial Sticker Labeling Machine

- Automatic Single Side Flat Bottle Sticker Labeling Machine

- Automatic Double Side (front & Back) Flat Bottle Sticker Labeling Machine

- Automatic Vertical Rotary Ampoule Sticker Labeling Machine

- Automatic Top Side Self Adhesive Sticker Labeling Machine

- Cosmetic Bottle Sticker Labeling Machine

- Automatic Lid Labeling Machine

- Standalone Sticker Labeling Machine Model Nksal -60s

- Manual Bottle Sticker Labeling Machine

- Square Bottle Wrap Around Sticker Labeling Machine

- Automatic Flameproof Sticker Labeling Machine

- Wet Glue Labeling Machine

- Shrink Sleeve Labeling Machine

- Sticker Labeling Machine

- Filling Machine

- Liquid Filling Machine

- Semi Automatic Tabletop Volumetric Liquid Filling Machine

- Automatic Double Head Volumetric Liquid Filling Machine

- Automatic Four Head Volumetric Liquid Filling Machine

- Automatic Six Head Volumetric Liquid Filling Machine

- Automatic Eight Head Volumetric Liquid Filling Machine

- Tabletop Manual Liquid Filling Machine

- Automatic Eye Drop Filling Sealing Machine

- Automatic Monoblock Filling & Capping Machine For Viral Transport Medium Kits

- Injectable Vial Filling & Rubber Stoppering Machine

- Cream Filling Machine

- Automatic Viscous Filling Machine

- Ampoule Filling And Sealing Machine

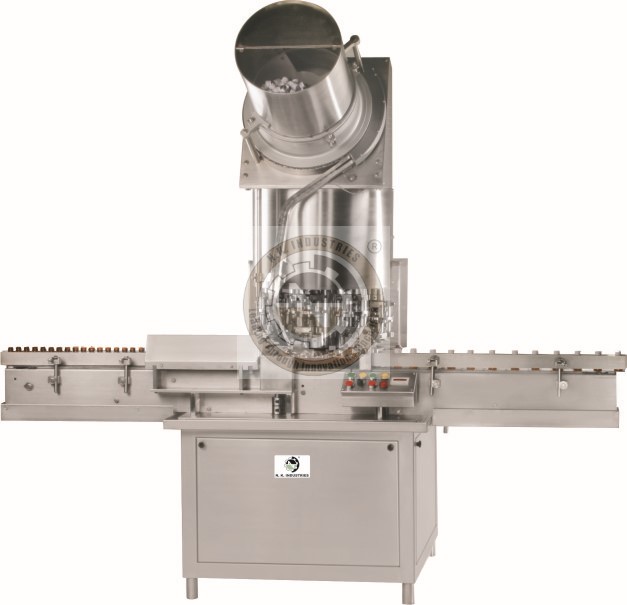

- Tablet Pill Capsule Counting Filling Machine

- Mineral Water Bottle Filling Machine

- Automatic Electronic Flowmeter Based Liquid Filling Machine

- Tube Filling Sealing Machine

- Liquid Filling Machine

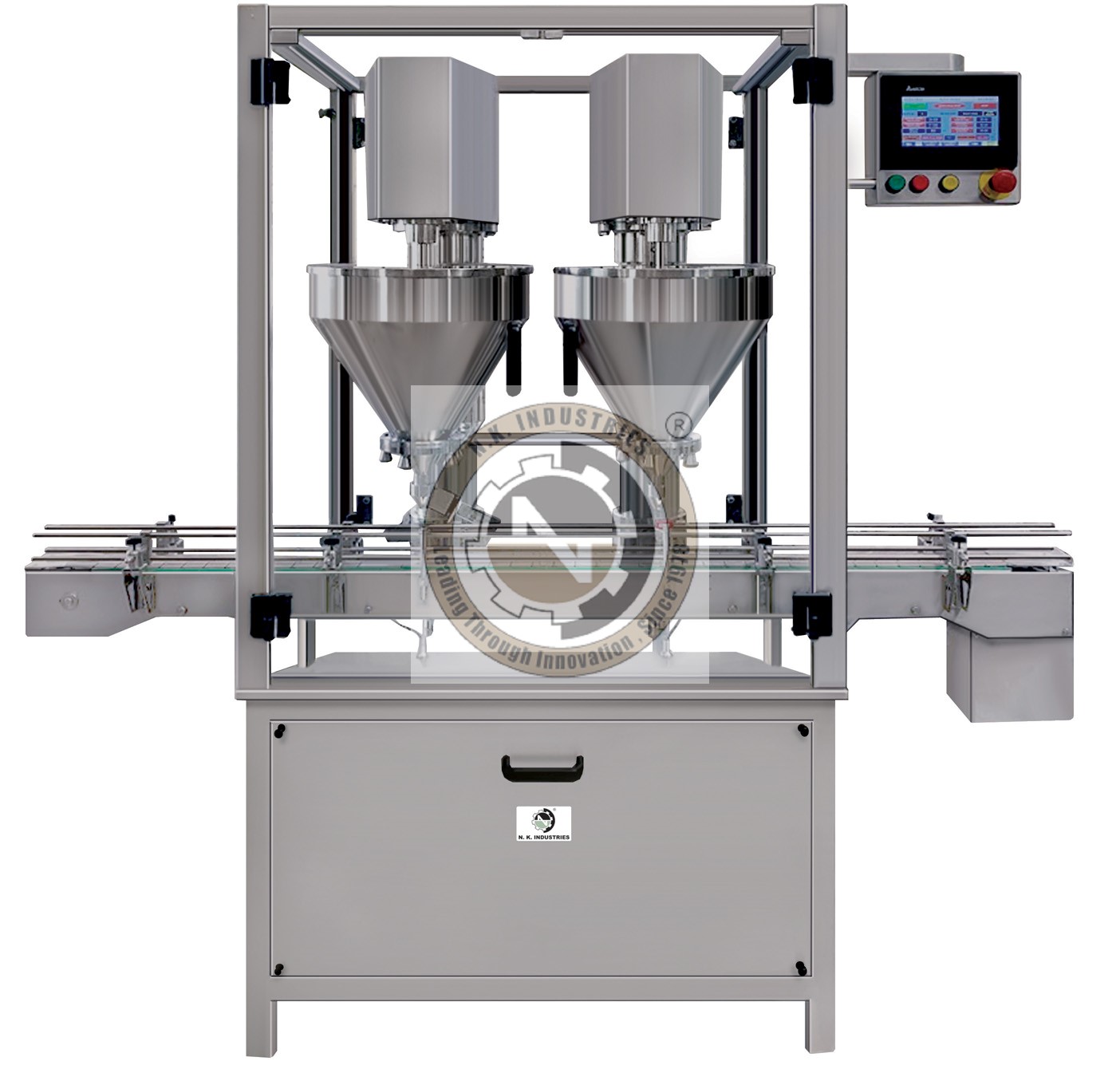

- Powder Filling Machine

- Vial Ampoule Inspection Machine

- Washing Machine

- Sterilization Tunnel

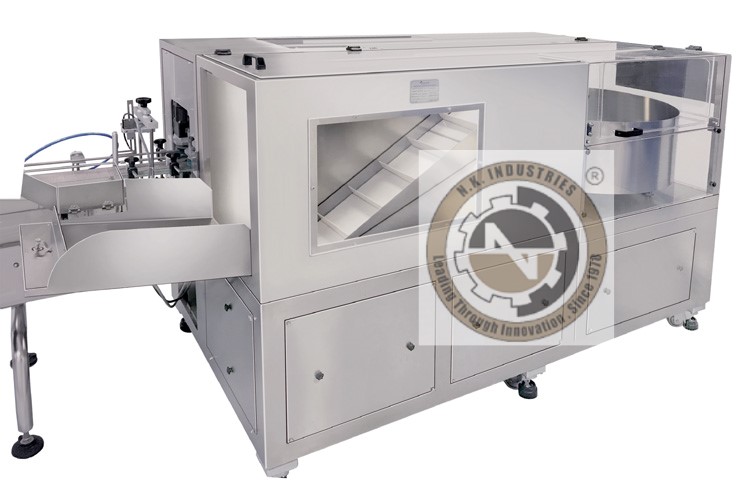

- Bottle Cleaning Machine

- Sealing Machine

- Packaging Machine

- Shrink Tunnel

- Automatic Bottle Unscrambler Machine

- Automatic Cotton Inserter Machine

- Automatic Sachet Silica Gel Pouch Inserter Machine

- Batch Coding Machine

- Blog

- Inquiry

- Contact Us