A TO Z GUIDE AS HOW TO SELECT BEST STICKER LABELING MACHINE FOR LABELING APPLICATION IN PACKAGING LINE

In today's advanced packaging lines, the self-adhesive sticker labeling machine is an essential component. This type of machine is primarily used to apply self-adhesive labels to containers such as bottles, vials, ampoules, jars, and more.

These self-adhesive labels are typically made from a variety of materials, including chromo paper and super sunshine paper, and are coated with pressure-sensitive adhesive on one side. Labels serve not only as a tool for branding but also as a medium to convey critical information such as the manufacturer's name, logo, product name, address, product characteristics, and barcodes. In the pharmaceutical industry, for instance, labels often include details such as batch numbers, manufacturing dates, and expiration dates. A well-applied label provides clear identification of a product and, by extension, the company, contributing to brand recognition and ultimately driving revenue growth.

Selecting the Right Sticker Labeling Machine

Given the significant role that sticker labeling machines play in enhancing product and brand visibility, it is crucial to select the right machine for your specific application. The choice of machine depends on several factors, including:

- Container Size: Consider the preferred diameter and height for round containers or the width and height for flat containers.

- Container Shape: The shape of the container (round, flat, oval, etc.) influences the type of labeling machine required.

- Number of Labels: Determine how many labels need to be applied to each container.

- Label Placement: Decide where on the container the labels need to be applied.

- Production Speed: Evaluate the required speed, measured in containers per minute.

- Automation Level: Determine whether a fully automatic or semi-automatic machine is needed based on production demands.

Once these fundamental details are established, selecting the appropriate sticker labeling machine becomes more straightforward. Below is an overview of the various types of sticker labeling machines available:

WRAP AROUND STICKER LABELING MACHINE:

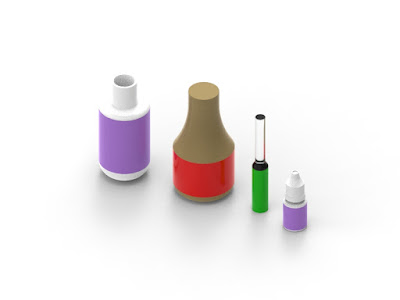

This machine is designed to apply a single label around the entire circumference of a round container, such as vials, glass bottles, or jars. Labels can be applied as a full wrap, partial wrap, or overlapping wrap, depending on the requirements. Commonly known as Automatic round bottle sticker labeling machines, they are available in various models, with production capacity largely influenced by factors such as label length, container diameter, and height. These machines can achieve speeds of up to 250 containers per minute. Examples of suitable containers include:

- Vials

- Glass bottles

- Round jars

|

| Type of Round bottle for Wrap around Round bottle Sticker Labeling Machine |

AUTOMATIC DOUBLE SIDE (FRONT AND BACK) STICKER LABELING MACHINE:

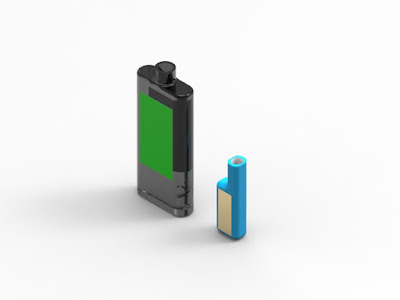

As the name suggests, this machine applies two labels simultaneously to the front and back of a container, which is typically flat, rectangular, or oval in shape. Multiple models are available, with production output depending on factors like label length, container shape, width, and height. These machines are also known as flat bottle sticker labeling machines or double-side sticker labeling machines. Examples of containers that can be labeled using this machine include:

- Flat bottles

- Rectangular containers

- Oval containers

|

| Type of Flat bottle for Sticker Labeling Machine Application |

AUTOMATIC TOP SIDE STICKER LABELING MACHINE:

This machine applies a single label to the top surface of a container, such as bottle closures, the top layer of fruit boxes, or CD covers. The label head is mounted vertically in relation to the machine's top plate to facilitate the labeling process. Examples of containers that can be labeled using this machine include:

- Bottle closures

- Fruit boxes

- CD covers

|

| Top Side Labeling Application |

AUTOMATIC HORIZONTAL STICKER LABELING MACHINE:

Horizontal sticker labeling machines are ideal for fully wrapping containers that are cylindrical and laid horizontally, such as test tubes and blood collection tubes. In this setup, the containers are loaded horizontally, and the labels are applied accordingly. Examples of containers suitable for this machine include:

- Test tubes

- Blood collection tubes

|

| Container for the Horizontal sticker labeling machine application |

Automatic vs. Semi-Automatic Sticker Labeling Machines

The decision to choose an automatic or semi-automatic sticker labeling machine largely depends on the customer's specific needs. Manual Bottle Sticker Labeling Machine or Semi-automatic sticker labeling machines are ideal for startup companies with lower production requirements but where accurate labeling is critical. These machines lack product feeding conveyors and cannot be integrated with upstream or downstream machines. Operators manually place containers into the labeling machine, and the labels are applied accordingly. Human intervention is higher, and output depends significantly on the operator's efficiency.

In contrast, automatic sticker labeling machines come equipped with conveyors and can be easily integrated into automated packaging lines. They are suitable for medium to high production environments, with minimal human intervention required beyond changing the self-adhesive roll and loading containers onto the feeding conveyor.

We hope this article has provided valuable insights into the different types of sticker labeling machines and their applications. If you have any questions or need further clarification, please leave a comment below, and we will be happy to assist you.

About the Author:

N.K Industries is a leading manufacturer, exporter, and supplier of a wide range of sticker labeling machines, including round bottle sticker labeling machines, automatic single-side flat bottle sticker labeling machines, automatic double-side flat bottle sticker labeling machines, ampoule sticker labeling machines, automatic top-side self-adhesive sticker labeling machines, manual bottle sticker labeling machines, and square bottle wrap-around sticker labeling machines.