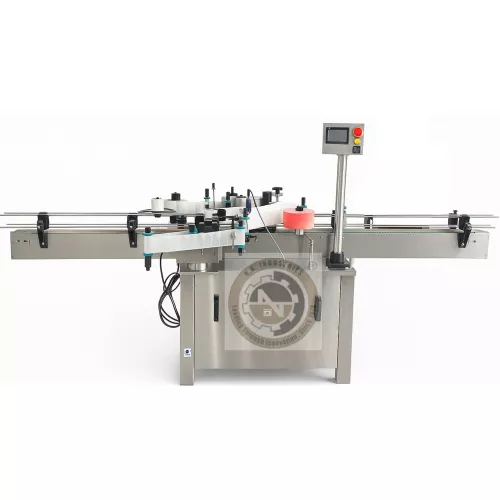

N.K Industries, headquartered in Ahmedabad, India, is a renowned manufacturer, exporter, and supplier of various models of Automatic Double Side Flat Bottle Sticker Labeling Machines, specifically designed for front and back labeling on flat, oval, and square bottles. Our machines are ideal for businesses in need of high precision, reliability, and efficiency in their labeling operations.

High-Performance Labeling for Diverse Container Shapes

The Automatic Double Side (Front & Back) Flat Bottle Sticker Labeling Machine is engineered to apply two labels simultaneously on the front and back of a wide range of container shapes, including round, flat, oval, and square bottles. Depending on the size of the labels and containers, this machine can label between 60 and 240 bottles per minute, making it an excellent choice for high-volume production environments.

Advanced Technology for Precision and Efficiency

This machine is equipped with the latest servo or stepper-controlled label dispensing system, ensuring precise and consistent label application. The advanced sensing system, which includes a unique background suppression photoelectric sensor, guarantees accurate container detection, minimizing errors and ensuring smooth operation.

To further enhance the machine’s flexibility, an optional wrap-around system is available, allowing the machine to apply single-side labels on flat bottles or wrap-around labels on round containers. This flexibility, combined with a design that requires no change parts for different label sizes, significantly reduces downtime and boosts productivity.