In the realm of modern packaging, ensuring product integrity and consumer safety is paramount. One critical component in achieving this is the capping process, which seals containers to prevent contamination, leakage, and tampering. Among the various capping solutions available, Roll-On Pilfer Proof (ROPP) capping machines stand out for their efficiency and reliability.

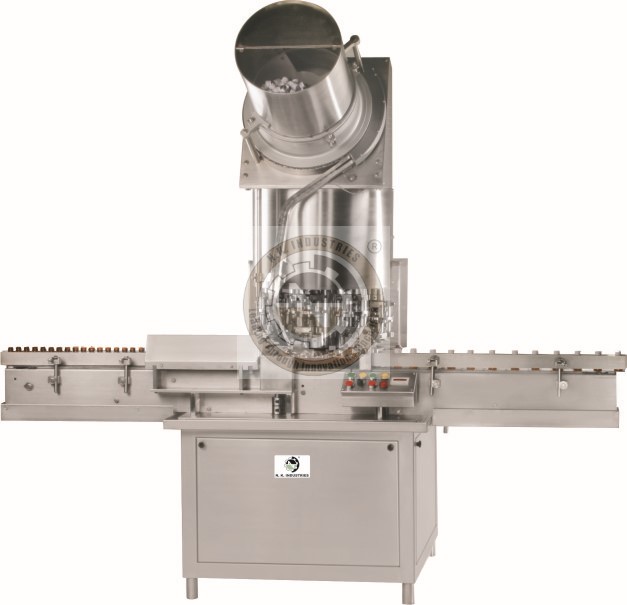

ROPP capping machines are designed to apply aluminum caps onto bottles, creating a tamper-evident seal that assures consumers of the product's authenticity. These machines are widely used across industries such as pharmaceuticals, beverages, cosmetics, and chemicals, where product safety and integrity are non-negotiable.

This comprehensive guide delves into the key features, benefits, and considerations when selecting a ROPP capping machine, with a spotlight on N.K Industries—a leading ROPP capping machine manufacturer and supplier.

II. Key Features of ROPP Capping Machines

A. Mechanism of Operation

ROPP capping machines operate by applying an unthreaded aluminum cap onto the bottle's neck. The machine's rollers then press and mold the cap to conform to the bottle's threads and sealing surface, creating a secure and tamper-evident closure.

Types of ROPP Capping Machines:

-

Semi-Automatic ROPP Capping Machines: Ideal for small to medium-scale operations, these machines require manual placement of bottles and caps, with the capping process being automated.

-

Automatic Single Head ROPP Capping Machines: Suitable for medium-scale production, these machines automate both the placement and capping processes, enhancing efficiency.

-

Automatic Multi-Head Rotary ROPP Capping Machines: Designed for high-speed, large-scale production lines, these machines feature multiple capping heads (ranging from 4 to 12) to cap several bottles simultaneously.

B. Design and Build Quality

The construction quality of ROPP capping machines significantly influences their durability and performance.

-

Materials Used: High-grade stainless steel (such as AISI 304) is commonly used for parts in contact with the product, ensuring hygiene and corrosion resistance.

-

Compactness and Space Efficiency: Modern ROPP capping machines are designed to occupy minimal floor space, making them suitable for facilities with space constraints.

C. Versatility and Compatibility

ROPP capping machines are engineered to handle a variety of bottle shapes and sizes, including round, square, and rectangular containers made of glass or plastic. They can accommodate different cap sizes (commonly 22mm, 25mm, and 28mm) with minimal changeover time, enhancing production flexibility.

D. Automation and Technology Integration

Advanced ROPP capping machines incorporate automation features to streamline operations:

-

Control Systems and User Interfaces: User-friendly interfaces, such as PLCs with HMI, allow operators to monitor and adjust machine settings easily.

-

Integration with Other Packaging Machinery: ROPP capping machines can be seamlessly integrated into existing production lines, working in tandem with filling, labeling, and packaging equipment.

III. Benefits of ROPP Capping Machines for Your Production Line

A. Enhanced Product Safety and Integrity

ROPP caps provide a tamper-evident seal, ensuring that any unauthorized access to the product is immediately noticeable. This feature is crucial for maintaining consumer trust, especially in industries where product integrity is vital.

B. Increased Efficiency and Productivity

Automated ROPP capping machines significantly boost production rates, with some models capable of capping up to 300 bottles per minute. This automation reduces manual labor requirements and minimizes human error, leading to consistent product quality.

C. Cost-Effectiveness

While the initial investment in ROPP capping machines may be substantial, the long-term savings are considerable. Reduced labor costs, minimized product wastage, and lower maintenance expenses contribute to a favorable return on investment.

D. Improved Brand Image

A securely sealed, tamper-evident product enhances brand credibility. Consumers are more likely to trust and repurchase products that demonstrate a commitment to safety and quality through secure packaging.

IV. Why Choose N.K Industries for ROPP Capping Machines

N.K Industries, based in Ahmedabad, India, is a renowned ROPP capping machine manufacturer and supplier with over 4 decades of experience. Their commitment to innovation and quality has positioned them as a trusted partner for businesses worldwide.

Key Offerings:

-

Diverse Product Range: From semi-automatic to fully automatic multi-head rotary machines, N.K Industries offers solutions tailored to various production scales.

-

Customization: Machines can be customized to handle specific bottle shapes, sizes, and production requirements.

-

Quality Assurance: Utilization of high-grade materials and adherence to GMP standards ensure durable and hygienic machinery.

-

After-Sales Support: Comprehensive support services, including installation, training, and maintenance, ensure optimal machine performance.

Notable Models:

-

NKCS-60R: An automatic single-head ROPP capping machine capable of capping up to 50 bottles per minute.

-

Multi-Head Rotary Machines: Available in 4, 6, 8, and 12-head configurations, these machines cater to high-speed production lines, with capacities ranging from 100 to 300 bottles per minute.

V. Conclusion

ROPP capping machines are integral to modern packaging lines, offering tamper-evident sealing, enhanced efficiency, and cost savings. Their versatility and compatibility with various bottle types make them a valuable asset across multiple industries.

Choosing the right ROPP capping machine manufacturer and supplier is crucial. N.K Industries' extensive experience, diverse product range, and commitment to quality position them as a leading choice for businesses seeking reliable capping solutions.

Investing in a high-quality ROPP capping machine not only safeguards your products but also reinforces your brand's commitment to quality and consumer safety.