Elevate Your Packaging with N.K Industries' Sticker Labeling Machines

In today’s fast-paced industrial landscape, the need for precision, speed, and efficiency in packaging cannot be overstated. At N.K Industries, we understand the pivotal role that labeling plays in brand recognition and regulatory compliance. As a pioneer manufacturer, exporter, and supplier of a comprehensive range of sticker labeling machines, we cater to a diverse array of industries, including pharmaceuticals, distilleries and breweries, cosmetics and toiletries, lube and edible oil, pesticides, and food. Our machines are designed to seamlessly integrate into your packaging line, ensuring that your products not only stand out on the shelves but also comply with industry standards.

The Growing Importance of Sticker Labeling Machines

As automation continues to revolutionize modern packaging lines, the self-adhesive sticker labeling machine has become an essential technology for industries aiming to enhance their brand visibility and streamline their packaging processes. These machines are indispensable for applying labels with precision and consistency, thereby augmenting the overall quality of the product presentation.

However, selecting the right self-adhesive sticker labeling machine is a critical decision that depends on several factors, including the shape of the container, the output needs of the packaging line, and the number of labels required per container. At N.K Industries, we recognize that one size does not fit all. That’s why we offer a diverse range of sticker labeling machines tailored to meet the specific requirements of various container shapes—whether it’s round, flat, oval, or even ampoules. Moreover, our machines are designed to handle different output capacities, ensuring that you find the perfect solution for your production line.

How Do Sticker Labeling Machines Work?

Understanding the working mechanism of a sticker labeling machine is crucial for making an informed purchasing decision. Our sticker labeling machines are equipped with state-of-the-art components such as PLC (Programmable Logic Controller), HMI (Human Machine Interface), the latest servo motor with a driver, gap sensors, and product sensors. These components work in harmony to deliver high precision and efficiency in labeling applications.

-

Container Reception: The process begins as the machine’s conveyor receives containers from the upstream machine. These containers have typically already been filled and sealed, ready for labeling.

-

Container Separation: The containers are then separated by a feeding roller assembly, which maintains a predetermined space between them based on the label length and container diameter. This precise spacing ensures that each label is applied accurately.

-

Label Application: Once the container reaches the labeling station, it is detected by a container sensor. The label is immediately placed on the container, ensuring instant adhesion of the label's edge. The accuracy of this process is paramount in preventing misalignment and ensuring a professional appearance.

-

Pressing Unit: After the label is applied, the container passes through a pressing unit. This unit ensures that the label is firmly attached to the container, resulting in precise registration and a crease-free labeling application. The end result is a perfectly labeled product ready for the market.

Why Choose N.K Industries’s Sticker Labeling Machines?

-

Versatility Across Industries: Our sticker labeling machines are designed to cater to a wide range of industries, each with its unique packaging requirements. Whether you are in the pharmaceutical industry, where precision and compliance are critical, or in the food and beverage sector, where speed and efficiency are paramount, our machines are up to the task. We offer solutions that are adaptable to various container shapes and sizes, ensuring that your labeling needs are met, regardless of the product you manufacture.

-

Advanced Technology Integration: At N.K Industries, we are committed to staying at the forefront of technological advancements. Our sticker labeling machines are equipped with the latest technology, including advanced servo motors, PLCs, and HMIs, which ensure smooth operation and high precision. The integration of gap and product sensors further enhances the accuracy of label placement, minimizing the risk of errors and rework.

-

Customization to Meet Specific Needs: We understand that each production line is unique, with specific requirements and constraints. That’s why we offer a high degree of customization in our sticker labeling machines. Whether you need a machine that handles round bottles at high speeds or one that can apply multiple labels on different sides of a container, we can tailor our solutions to meet your exact specifications.

-

Quality and Durability: Quality is the cornerstone of our manufacturing process. We use high-quality metallurgical compositions and CE-certified electronic components to ensure that our machines are not only efficient but also durable. This commitment to quality translates into longer machine life, reduced maintenance costs, and a higher return on investment for our customers.

-

Global Reach and Support: With a strong presence in the international market, N.K Industries has built a reputation for reliability and excellence. Our sticker labeling machines are exported to various countries, and we provide comprehensive after-sales support to ensure that our customers receive the maximum value from their investment. Whether you need technical assistance, spare parts, or training, our team of experts is always ready to help.

Explore Our Range of Sticker Labeling Machines

At N.K Industries, we take pride in offering a wide range of sticker labeling machines, each designed to meet specific packaging needs. Here’s a closer look at some of our flagship models:

-

Automatic Round Bottle Sticker Labeling Machine: Designed for high-speed labeling of round bottles, this machine is perfect for industries that require rapid and precise label application. It can handle various bottle sizes and is ideal for sectors such as pharmaceuticals and beverages.

-

Automatic Lid Labeling Machine: This machine is specifically engineered to apply labels on the lids of containers, ensuring that your product branding is consistent across all surfaces. It’s a popular choice for food and cosmetics industries where lid labeling is essential.

-

Automatic Single Side Flat Bottle Sticker Labeling Machine: For products packaged in flat bottles, this machine offers an efficient solution for applying labels on a single side. It’s commonly used in the personal care and lube oil industries.

-

Automatic Top Side Self-Adhesive Sticker Labeling Machine: This versatile machine is designed to apply labels on the top surface of containers, making it ideal for labeling jars, tins, and other similar packaging formats. It’s widely used in the food and cosmetics industries.

-

Automatic Vertical Rotary Ampoule/Vial Sticker Labeling Machine: Specifically designed for the pharmaceutical industry, this machine provides precise labeling for ampoules and vials. Its rotary design ensures that even the smallest containers are labeled accurately and efficiently.

-

Cosmetic Bottle Sticker Labeling Machine: Tailored for the cosmetics industry, this machine handles various bottle shapes and sizes, ensuring that your products have a professional and attractive appearance on the shelves.

-

Manual Bottle Sticker Labeling Machine: For smaller production runs or artisanal products, our manual sticker labeling machine offers a cost-effective solution. It’s easy to operate and provides consistent labeling quality, making it ideal for startups and small businesses.

-

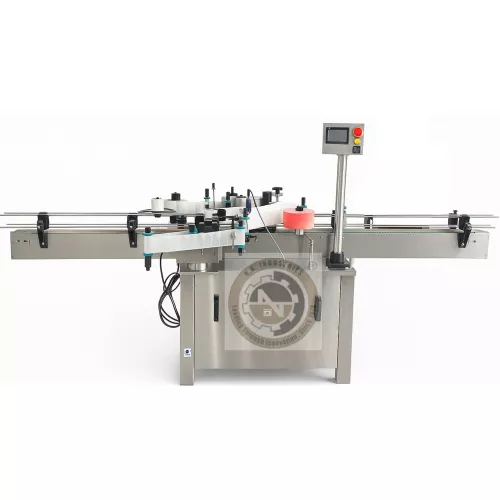

Standalone Sticker Labeling Machine: This machine is designed to operate independently of the main production line, offering flexibility in labeling operations. It’s suitable for various container shapes and sizes and is perfect for businesses that require additional labeling capacity.

-

Automatic Vial Sticker Labeling Machine: Engineered for the pharmaceutical industry, this machine provides high-speed labeling for vials, ensuring that your products meet industry standards for labeling accuracy and compliance.

-

Square Bottle Wrap Around Sticker Labeling Machine: This machine is designed to apply wrap-around labels on square bottles, providing a 360-degree branding solution. It’s commonly used in the food and beverage industry.

-

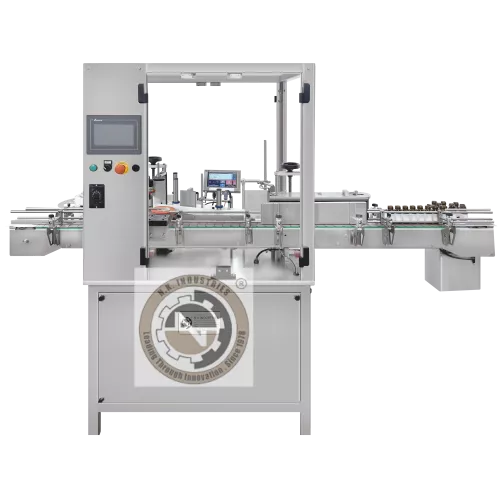

Automatic Double Side (Front & Back) Flat Bottle Sticker Labeling Machine: For products that require labels on both the front and back, this machine offers a seamless solution. It’s ideal for personal care products, household cleaners, and more.

-

Automatic Flameproof Sticker Labeling Machine: Safety is paramount in certain industries, and our flameproof sticker labeling machine is designed to operate in hazardous environments. It’s the perfect choice for industries dealing with flammable substances.

Conclusion: N.K Industries is Your Partner in Labeling Excellence

In an era where packaging plays a crucial role in product differentiation and regulatory compliance, investing in the right sticker labeling machine is a strategic decision. At N.K Industries, we are committed to providing our customers with cutting-edge labeling solutions that enhance their product presentation and streamline their packaging processes.

Our extensive range of sticker labeling machines is designed to meet the diverse needs of various industries, ensuring that you find the perfect fit for your production line. With a focus on quality, customization, and customer support, N.K Industries is your trusted partner in packaging excellence.

Whether you’re looking to upgrade your existing labeling equipment or are in need of a new solution, our team of experts is here to assist you. Contact us today to learn more about our sticker labeling machines and how they can transform your packaging operations.