In the dynamic and highly competitive landscape of manufacturing, the importance of efficient powder filling processes cannot be overstated. Whether in the pharmaceutical, food, chemical, or cosmetic sectors, manufacturers face increasing pressure to deliver products that are not only high in quality but also precisely measured and hygienically packaged. In such a scenario, powder filling technology plays a pivotal role in optimizing production output, reducing product wastage, and maintaining stringent quality control standards.

One of the most advanced and dependable systems in the realm of powder packaging is the Auger Powder Filling Machine. These machines are designed to offer high levels of accuracy, repeatability, and flexibility. Utilizing a rotating screw mechanism known as an auger, these machines are capable of filling powders into containers with unmatched precision. The growing demand for automation, regulatory compliance, and increased productivity has further fueled the adoption of auger-based filling technologies.

This comprehensive guide aims to equip readers with in-depth knowledge about Auger Powder Filling Machines, outlining their functionality, benefits, and wide-ranging applications. Additionally, it provides a detailed look at the specific models offered by N.K. Industries—an industry-leading manufacturer, supplier, and exporter of premium powder filling machines. Whether you're a business looking to upgrade from manual filling methods or seeking high-speed, high-accuracy solutions for bulk production, this guide will help you make an informed decision.

II. Understanding Auger Powder Filling Machines

A. Definition and Working Principle

An Auger Powder Filling Machine is a type of volumetric filling equipment that uses an auger screw to accurately dispense powdered substances into containers. The auger screw rotates at a programmed speed and time, delivering a set quantity of powder based on the number of rotations or screw pitch. This dispensing method ensures consistent dosing regardless of operator intervention or variations in powder characteristics.

These machines are particularly effective in dealing with both free-flowing and non-free-flowing powders. Free-flowing powders like talcum or salt flow easily, whereas non-free-flowing powders like flour or milk powder tend to clump and require agitation for even dispensing. The auger mechanism can be combined with agitators and hopper vibrators to manage various powder behaviors and ensure continuous, clog-free operations.

B. Advantages of Auger Technology

-

High Dosing Precision: Auger fillers are designed to offer extremely accurate fills, minimizing overfill and product giveaway.

-

Versatility Across Products: They can handle powders of varying particle sizes, cohesiveness, and densities.

-

Hygienic Design: Ideal for pharmaceutical and food-grade environments, as the contact parts are easy to clean and can be made from SS316.

-

Scalability: Auger technology can be easily scaled from lab-size semi-automatic models to high-speed automatic filling lines.

-

Dust Control: Enclosed filling nozzles reduce dust generation, which is particularly important in cleanroom applications.

-

Custom Fill Volumes: Machines can be calibrated for fill sizes ranging from a few milligrams to multiple kilograms.

-

Reduced Downtime: Modular design facilitates quick changeovers and minimal maintenance.

C. Applications Across Various Industries

Auger Powder Filling Machines have broad applicability across diverse industrial sectors:

-

Pharmaceutical Industry: Ideal for filling antibiotic powders, dry syrups, nutraceuticals, protein supplements, and other sensitive formulations requiring high precision.

-

Food and Beverage Industry: Used for packing spices, protein powders, baking ingredients, coffee, milk powder, and nutritional supplements.

-

Chemical Industry: Suitable for packaging powdered chemicals, desiccants, agrochemicals, pigments, and industrial compounds.

-

Cosmetics Industry: Used to fill face powders, compact powders, and other powdered personal care products.

-

Household Products: Effective for filling powdered detergents, floor cleaners, bleaching agents, and similar products.

III. Semi-Automatic Auger Powder Filling Machine

N.K. Industries' Semi-Automatic Auger Powder Filling Machine is designed to serve small to medium-scale operations with consistent and precise powder filling requirements. Built with a user-centric approach, this machine bridges the gap between manual filling and full automation.

A. Features and Specifications

-

Filling Capacity: Flexible filling range from 5 grams to 1000 grams.

-

Material Versatility: Can fill powders, granules, and paste-type products.

-

Adaptable Design: Compatible with bottles, jars, pouches, and containers of various shapes and sizes.

-

Ease of Use: Simple control panel allows users to adjust filling volumes quickly.

-

Tool-less Changeover: Quick adjustments allow for efficient batch-to-batch transitions.

-

Compact Footprint: Ideal for businesses with limited floor space.

B. Benefits of Using a Semi-Automatic Machine

-

Cost-Effective: Offers a great return on investment for businesses transitioning from manual methods.

-

Reduces Human Error: Increases accuracy and consistency in filling volumes.

-

Low Maintenance: Fewer moving parts mean reduced maintenance and lower total cost of ownership.

-

Training-Friendly: Minimal technical knowledge is required to operate.

C. Ideal Use Cases and Container Types

The Semi-Automatic Auger Powder Filling Machine is particularly useful for:

-

Small batch pharmaceutical preparations

-

Laboratory-scale product development

-

Specialty food item packaging

-

Small-scale nutraceutical production

-

Cosmetic and personal care product lines

IV. Automatic Auger Powder Filling Machines

For operations requiring greater throughput and automation, N.K. Industries offers a range of high-performance Automatic Auger Powder Filling Machines. These machines integrate advanced technologies to deliver superior efficiency, precision, and speed.

A. Single Head Automatic Auger Powder Filling Machine (Model NKAPF-100)

-

Features and Specifications of Single Head Automatic Auger Powder Fillng Machine

-

Output Capacity: Up to 30 bottles per minute for 5 gms and 10 gms fill volumes.

-

Indexing System: High-speed indexing system ensures seamless container movement.

-

Electromagnetic Clutch Brake: Provides precision in dosing.

-

Optional Servo Motor: Enables real-time correction for extremely precise fills.

-

Touch Screen HMI: User-friendly interface for monitoring and controlling operations.

-

Stainless Steel Build: Built as per GMP guidelines with SS304 or SS316 contact parts.

-

Applications and Advantages

-

Mid-volume Production Lines: Perfect for growing operations looking to scale up.

-

Nutraceuticals and Dietary Powders: Delivers accurate fills without contamination.

-

Dry Syrup Lines: Compatible with automation in bottle handling and capping.

-

Time-saving: Reduces labor hours while maintaining accuracy.

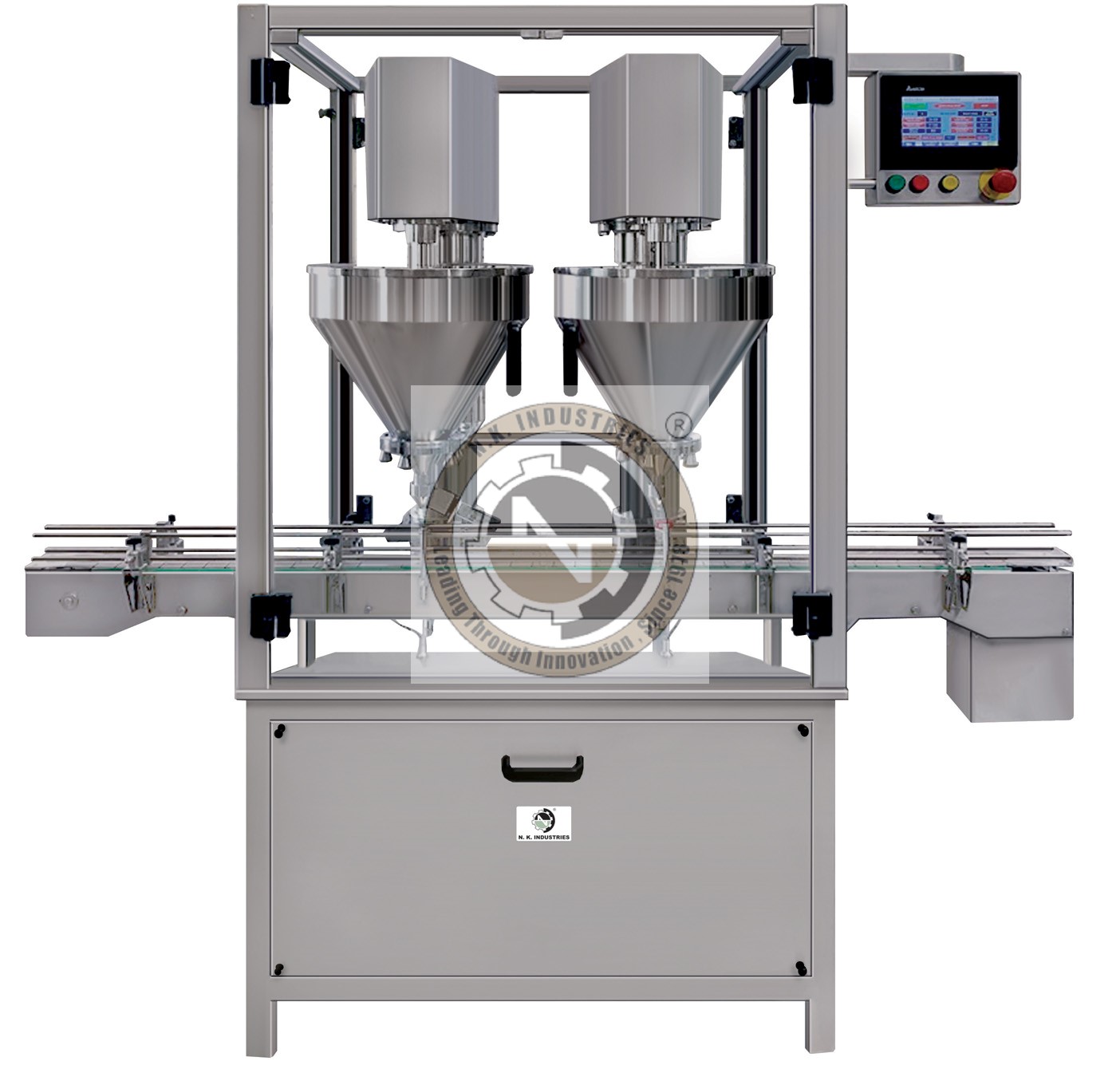

B. Automatic Double Head Auger Powder Filling Machine (Model NKAPF-200)

-

Features and Specifications

-

Dual Filling Heads: Simultaneous dual filling mechanism for higher output.

-

Output Capacity: Up to 70 bottles per minute for standard doses.

-

Flexible Integration: Can be linked with upstream and downstream equipment.

-

Advanced Safety Systems: Ensures zero spillage and operator safety.

-

Servo Control Compatibility: Available with servo-based drive for enhanced dosing control.

-

GMP Compliant Design: Suitable for cleanroom installations.

-

Applications and Advantages

Advantages of Double Head Auger Powder Filling Machine is as below:

-

Large Scale Production: Ideal for pharmaceutical and nutraceutical manufacturers with high-volume requirements.

-

Protein Supplements & Health Powders: Perfect for high-speed bottling lines.

-

Food and Beverage: Can be integrated with labeling and capping machines for turnkey solutions.

-

Reduced Downtime: Dual heads increase speed and decrease overall production time.

V. Conclusion

The adoption of Auger Powder Filling Machines represents a significant leap forward for manufacturers seeking reliability, consistency, and efficiency in powder packaging. From semi-automatic units suited for small-scale production to high-speed automatic machines for bulk operations, auger fillers cater to a broad spectrum of operational needs.

When selecting the right machine, factors such as powder characteristics, required fill volume, container type, and output requirements must be carefully considered. Investing in the right model ensures not only immediate productivity gains but also long-term operational savings and quality consistency.

N.K. Industries, a trusted name in the industry, brings to the table decades of experience, state-of-the-art manufacturing facilities, and a global client base. With a strong focus on quality, performance, and innovation, N.K. Industries continues to lead the way as a preferred manufacturer, supplier, and exporter of Auger Powder Filling Machines.

Choose N.K. Industries to experience excellence in powder filling solutions that elevate your production standards while meeting stringent industry regulations.

Author: N.K. Industries

With over three decades of experience and 2500+ successful installations across the globe, N.K. Industries is a leading manufacturer, supplier, and exporter of powder filling machines, including Semi-Automatic, Single Head, and Double Head Auger Powder Filling Machines. We specialize in providing robust machinery for pharmaceutical, food, chemical, cosmetic, and household product industries.